Zhangjiagang Jiayuan ماشین آلات CO.، LTD

تولید کننده حرفه ای مایع آشامیدنی و بسته بندی ماشین آلات

| Place of Origin: | JiangSu China |

| نام تجاری: | JiaYuan |

| گواهی: | CE SGS |

| Model Number: | RCGF16-12-6 |

| Minimum Order Quantity: | 1 set |

|---|---|

| قیمت: | USD 18000-18500 per set |

| Packaging Details: | This machine would be wrapped up by plastic films. and covered up by extra padding like cartons and with lots of poly foams applied all around. and then put into a 2300*1700*2400 mm solid wooden case. And this whole process can be strictly customized. |

| Delivery Time: | 30 days |

| Payment Terms: | Western Union, L/C, T/T |

| Supply Ability: | 10 sets per month |

| After Sale Service: | overseas | Dimension: | 2100*1500*2200 |

|---|---|---|---|

| Certificates: | CE SGS | Weight: | 2500kg |

| Brand: | JiaYuan | Power: | 5.8kw |

| Voltage: | 220/380V | Model Number: | RCGF16-12-6 |

| Driven Type: | Electric | Automatic Grade: | Automatic |

| Application: | Beverage | Packaging Material: | PET plastic |

| Packaging Type: | Bottles | Capacity: | 3000BPH |

| Bottle Volume: | 300ml-2500ml | Machine Control: | Siemens PLC System |

| Filling Method: | Hot filling | Filling precision: | Within error of 5mm of liquid level |

| Cap type: | Plastic screw cap | ||

| برجسته کردن: | ,,pet bottle filling line |

||

Siemens PLC System juice bottling machine for Flavoured Beverage Production Line

Briefs on Product

a. This type of small juice filling machine is for the juice production line.

b. Heavy duty 304 stainless steel welded frame, 316 stainless steel hygienically processed filling nozzles andcapping heads.

c. Siemens PLC system along with Omron photoelectric sensor make this machine smart.

d. 7-inch touch screen tames this steel beast perfectly.

e. The capacity is around 3000 bottles per hour.(up to 4000bph)

f. The filling nozzle stroke is adjustable to the different volumes of bottle.(200ml-2500ml)

g. Faster and more effective product and bottle changeover reduces your product losses.

h. Hygienic design for easy resource-saving sanitizing. juice bottling machine

Having been proved by certificates like SGS, CE.

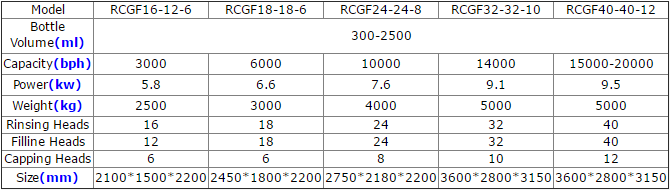

Products of RCGF series

Detailed Description and Images

Rinsing: The rinser clutches bottles from the starwheel, holding bottles by their necks. gradually turn them upside down while rotating, It will send the bottles to the rinsing area where spraying water come from up above, washing bottles throughly.small juice filling machine

Hot Filling: In order to avoid any kind of shape change while doing hot filling, The bottles will be grabbed at their necks. Once bottles in the right position, those filling nozzles move down half inside the bottles. The outlet channel of the filling valve opens up, and the hot liquid(tempereture ranges from 85 to 95 degrees celsuis) flows down. As the bottles getting filled up, the inlet channel opens up to allow the superfluous amount to flow back. This whole process makes sure bottles get fully filled.

The temperature of the liquid is monitored, and the backup recirculation system allows the liquid to flow back from the filling station once the tmperature drops down blew the pre-set.

Rinsing: The rinser clutches bottles from the starwheel, holding bottles by their necks. gradually turn them upside down while rotating, It will send the bottles to the rinsing area where spraying water come from up above, washing bottles throughly.small juice filling machine

Hot Filling: In order to avoid any kind of shape change while doing hot filling, The bottles will be grabbed at their necks. Once bottles in the right position, those filling nozzles move down half inside the bottles. The outlet channel of the filling valve opens up, and the hot liquid(tempereture ranges from 85 to 95 degrees celsuis) flows down. As the bottles getting filled up, the inlet channel opens up to allow the superfluous amount to flow back. This whole process makes sure bottles get fully filled.

The temperature of the liquid is monitored, and the backup recirculation system allows the liquid to flow back from the filling station once the tmperature drops down blew the pre-set.

Capping: Bottles will be sent over to the capping station, Cap sorter will put a cap onto each bottle, and then thephotoelectric sensor enhanced capper will do the swiveling motion to tighten the cap.

|

a. Plier-like clutches could easily hook up bottle's neck without doing any damage. |

|

a. 316 stainless steel made filling nozzles, sanitarily reliable and durable. |

|

|

a. Made of stainless steel 316, ensuring durability. |

Quality Assurance

Company info

Company Information:

We locate in ZhangJiaGang, a small city near ShangHai. We have several certificates such as CE,SGS,etc. we have a batch of decent manufacturing facilities, professional staff, diligent and farsighted leadship. Our machines are widely sold domestically and abroad. We've been majoring in complete beverage production line, including pure/mineral water production line, non-carbonated drinks production line, carbonated drinks production line.

Packaging and Shipping

Our Service

1. If you are interested

a. Contact us for more detailed info, We are willing to answer your questions.

b. We highly recommend you come to our factory to check out the machine personally, You would be picked up and treated with a warm reception.

2. Customized service

a. We could design and build the machines according to your requirements(material, power, filling method, type of bottle, some certain modules, etc). Meanwhile, we could also give you professional suggestions.

b. We also offer turnkey project, help you design production-line layout and train skilled employees who are able to operate properly.

3. After-sales service

a. We set your shopping experience as our top priority, we will produce as exactly you require and let you get your machine as soon as possible.

b. Our engineers will arrive at your factory right after the machine's arrival. They will help install the machine and teach your employees how to operate properly.

c. We provide one year warranty with free spare components.

6000 Bph PET Water Bottle Filling Machine / Auto Water Bottling Equipment

5L Automatic Water Bottle Filling Machine 2500Bph / 3 In 1 Bottle Filling Equipment

دستگاه پرکن بطری آب 20000 بشکه برای بطری HDPE، دستگاه پرکن آب

CGF40-40-12 Water Bottling Equipment / Automatic Liquid Bottle Filling Machine

ماشین ظرفشویی کاملا اتوماتیک 4000BPH برای بطری PET گرد

ماشین ظرفشویی آبپاش بطری 6000BPH Ectric Cans دستگاه پرکن داغ

3 در 1 دستگاه آبکاری بتلنج تجهیزات فولاد ضد زنگ / دستگاه بسته بندی پر کردن

Crown Cap Beer Bottle Filling Machine 3500 BPH Glass Bottling Machine

3000 BPH Water Glass Bottle Filling Machine With Twist off Cap , Hot Filling Machine

Carbonated Drink Automatic Glass Bottle Filling Machine 8000BPH with Crown Cap

Glass Bottle Carbonated Drink Filling Machine 5000BPH Glass Bottle Filler